Synthesis of High-purity Fe2AlB2 and the Effect as Sintering Additive for ZrB2

WANG Rui, XU Wen-Tao, QIN Zi-Xuan, LING Jun-Rong and ZHOU You-Fu*

Chin. J. Struct. Chem. 2021, 40, 283-290 DOI: 10.14102/j.cnki.0254-5861.2011-2882

March 15, 2021

MAB phase, ternary layered structure, high purity, ZrB2

ABSTRACT

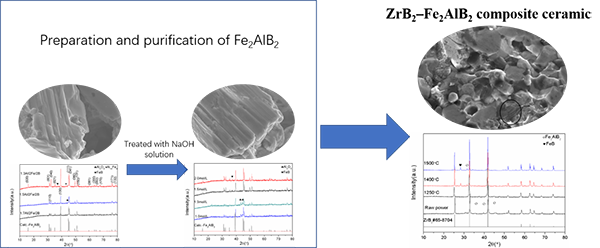

Fe2AlB2 powder material was prepared by the direct

reaction of iron, aluminum and boron powders in a tubular furnace. The effects

of different Al contents, temperature and raw material pretreatment on the

purity of product were studied. The mixed powder with the stoichiometric ratio of

1.5Al/2Fe/2B was processed by CIP (Cold Isostatic Pressing), and then calcined

at 1150 ℃ for 120

min. The product containing a small amount of impurities is treated with alkaline

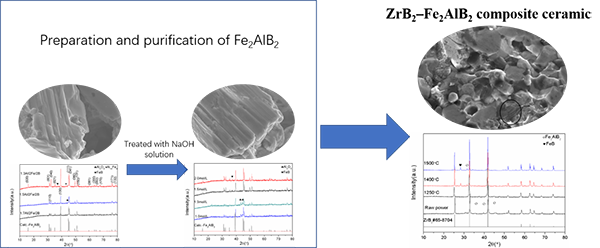

solution to obtain high-purity Fe2AlB2 powder. ZrB2-Fe2AlB2 composite ceramic was successfully prepared at 1250 ℃ by hot pressing sintering. The density, hardness and fracture

toughness were 96.2%, 22 ± 0.3 GPa and 5.78 ± 0.5 MPa·m1/2,

respectively.