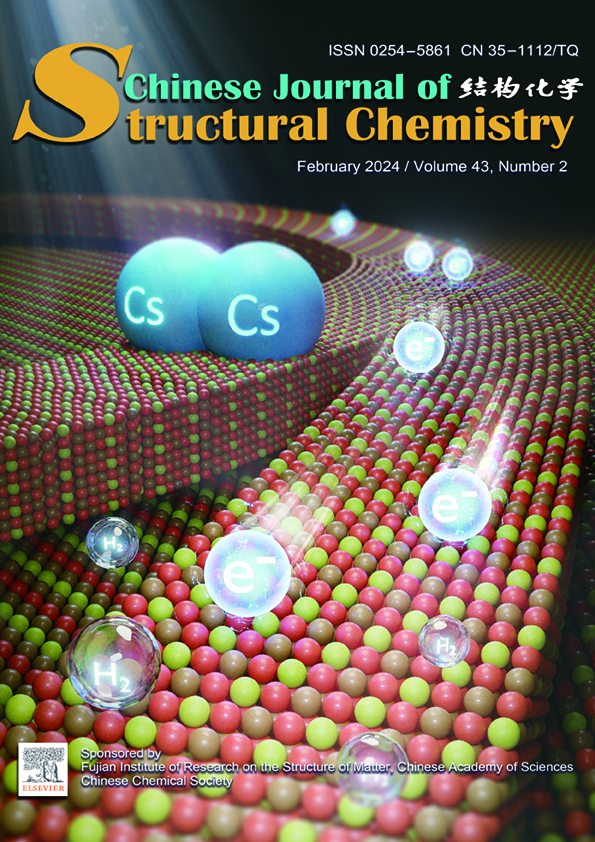

Jiangping Chen, Hongju Ren, Kai Wu, Huihuang Fang*, Chongqi Chen, Li Lin, Yu Luo*, Lilong Jiang

Chin. J. Struct. Chem., 2024, 43: 100236. DOI: 10.1016/j.cjsc.2024.100236

February 15, 2024

Metal-support interaction; Ammonia decomposition; Nickel; Cerium oxide; Metal-oxide interfaces

ABSTRACT

The ammonia decomposition for the production of carbon-free hydrogen has triggered great attention yet still remains challenging due to its sluggish kinetics, posting the importance of precise design of efficient catalysts for ammonia decomposition under low temperatures. Constructing the metal-support interaction and interface is one of the most important strategies for promoting catalysts. In this work, by coating ceria onto the Ni nanoparticles (NPs), we discover that the Ni–CeO2 interfaces create an exceptional effect to enhance the catalytic decomposition of ammonia by over 10 folds, compared with the pristine Ni. The kinetic analysis demonstrates that the recombinative N2 desorption is the rate-determining step (RDS) and the Ni–CeO2 interface greatly increases the RDS. Based on these understandings, a strategy to fabricate the Ni/CeO2 catalyst with abundant Ni–Ce–O interfaces via one-pot sol-gel method was employed (hereafter denoted to s–Ni/CeO2). The s–Ni/CeO2 catalyst shows a high activity for ammonia decomposition, achieving a H2 formation rate of 10.5 mmol gcat−1 min−1 at 550 °C. Combined with a series of characterizations, the relationship between the catalyst structure and the performance was investigated for further understanding the effect of metal-oxide interfaces.